From Oct. 24-26, the South’s manufacturing industry participated in the region’s largest biannual manufacturing event when SOUTHTEC 2023 returned to the Greenville Convention Center. SOUTHTEC, which also is the longest-standing manufacturing event in the South, has been conducted for more than 30 years by SME, Manufacturing is the backbone of Greenville’s economy, where 60,500 people, or 13.3% of the population, are employed in the industry. That’s why over 7,000 manufacturing workers and nearly 350 exhibitors participated this year.

From Oct. 24-26, the South’s manufacturing industry participated in the region’s largest biannual manufacturing event when SOUTHTEC 2023 returned to the Greenville Convention Center. SOUTHTEC, which also is the longest-standing manufacturing event in the South, has been conducted for more than 30 years by SME, Manufacturing is the backbone of Greenville’s economy, where 60,500 people, or 13.3% of the population, are employed in the industry. That’s why over 7,000 manufacturing workers and nearly 350 exhibitors participated this year.

SOUTHTEC’s regional nature attracts manufacturers of all sizes, including small-to-medium-size manufacturers (SMMs) that rely on the event for technical information, business strategy and networking opportunities with industry experts and thought leaders. In fact, 53% of attendees came from facilities with 50 or less employees.

The event addresses two key goals of SME: advance manufacturing technology in the industry, including smart manufacturing and additive manufacturing, and expand the workforce and its capabilities. In support of this two-pronged mission, this year’s SOUTHTEC event featured a new lineup of keynote and thought-leadership panel discussions from three industry organizations designed to advance these goals and drive them further into the manufacturing base.

Thought Leadership at SOUTHTEC

Tooling U-SME — Tuesday’s SOUTHTEC speaker lineup in the Smart Manufacturing Theater was focused on education and workforce development and was presented by Tooling U-SME, the workforce development division of SME. The organization works with manufacturers, educators, workforce development agencies and others, to empower organizations to magnify their productivity, efficiency and profitability.

The first keynote session focused on the transformation in education taking place to meet industry needs. It spotlighted the journey of local institution Greenville Technical College’s School of Advanced Manufacturing and Transportation Technology, whose pioneering program immerses students in the world of CNC, welding, automotive technology and mechatronics.

Presenter Raymond L. James, the dean of the school, said the two-year program, which is designed to augment students’ associate degrees, produces graduates ready to assume technical and managerial leadership roles in today’s high-tech manufacturing sector. Co-presenter Deb Volzer, director of government and workforce partnerships for SME, said students not only secure good jobs but also can lock in rewarding careers following graduation.

Presenter Raymond L. James, the dean of the school, said the two-year program, which is designed to augment students’ associate degrees, produces graduates ready to assume technical and managerial leadership roles in today’s high-tech manufacturing sector. Co-presenter Deb Volzer, director of government and workforce partnerships for SME, said students not only secure good jobs but also can lock in rewarding careers following graduation.

The session also featured remarks and discussion with Greenville Technical College Academic Program Directors Matthew Brady, Casey Ross and Willie Thompson, and Department Head Marvin Bostic.

Tuesday’s keynote lineup also included a discussion among South Carolina manufacturers regarding innovative solutions for workforce recruitment and retention in the local industry. Andy Carr, president and CEO of the South Carolina Manufacturing Extension Partnership and William Floyd III, director of the South Carolina Department of Employment & Workforce, kicked off the session. They were joined in the second hour by industry leaders from South Carolina who discussed insights into their journey, including small wins and setbacks, sharing how to deploy innovation as a workforce recruitment and retention strategy.

A third session on Tuesday shared a message about the importance of connecting workforce development and economic development. It featured examples of custom training programs developed at Greenville Technical College in partnership with business partners that exactly met their training and workforce development needs.

CESMII – The Smart Manufacturing Institute — Wednesday’s thought-leadership sessions were presented by CESMII and were focused on how U.S. smart manufacturing strategies and priorities can align to accelerate the realization of sustainable and competitive manufacturing supply chains.

The sessions presented a vision for smart manufacturing in the U.S. and how manufacturers are facilitating more rapid development, deployment and adoption of smart manufacturing technologies and workforce development strategies. The sessions also examined a national strategy for smart manufacturing through a look at the new U.S. “National Plan for Smart Manufacturing,” and the recommendations that were made to Congress. It also discussed how a bilateral partnership between the U.S. and Germany can drive harmonization for a global manufacturing ecosystem and foster the innovation necessary for sustainable growth in the manufacturing sector.

The sessions presented a vision for smart manufacturing in the U.S. and how manufacturers are facilitating more rapid development, deployment and adoption of smart manufacturing technologies and workforce development strategies. The sessions also examined a national strategy for smart manufacturing through a look at the new U.S. “National Plan for Smart Manufacturing,” and the recommendations that were made to Congress. It also discussed how a bilateral partnership between the U.S. and Germany can drive harmonization for a global manufacturing ecosystem and foster the innovation necessary for sustainable growth in the manufacturing sector.

The afternoon panel session sought to demystify the convergence of Operations Technology and Information Technology systems that over several decades have become separately entrenched. The panel discussed several truths and debunked a number of myths about the pathway to achieving convergence. The group determined that manufacturing leaders must embrace the concepts that Industry 4.0 and Smart Manufacturing offer to deliver solutions that enable their stakeholders to manage manufacturing supply chains around value streams and business functions seamlessly across legacy OT and IT boundaries.

Manufacturing USA — Thursday’s thought-leadership sessions were about helping the audience get to know Manufacturing USA, the network of public-private partnerships designed to secure U.S. global leadership in advanced manufacturing through large-scale collaboration on technology, supply chain and workforce development. Known as institutes, the 16 organizations that make up Manufacturing USA convene business competitors, academic institutions, government entities and other stakeholders to test applications of new technology, create new products, reduce cost and risk, and enable the manufacturing workforce with important skills for the future.

The afternoon session from Modern Makers from Manufacturing USA presented stories and case studies about engaging high-tech careers and the different pathways these Modern Makers have taken that are helping shape the future of manufacturing.

Bright Minds Program Offerings Encourage Manufacturing Knowledge, Experience

One of the programs present at most SME events in 2023 that engage high school students is the SME Education Foundation’s Bright Minds Student Summit. Student summits are designed to expose high school students, oftentimes for the first time, to cutting-edge manufacturing technology and introduce them to leading companies and individuals driving transformational change within the industry.

One of the programs present at most SME events in 2023 that engage high school students is the SME Education Foundation’s Bright Minds Student Summit. Student summits are designed to expose high school students, oftentimes for the first time, to cutting-edge manufacturing technology and introduce them to leading companies and individuals driving transformational change within the industry.

SOUTHTEC’s Bright Minds Student Summit hosted more than 200 Greenville-area students learning from manufacturing leaders, and also experiencing technology on the exhibition floor from leading companies. Using gamification, the summit helped the students learn in a fun environment, with the winning team of five each winning a 3D printer, courtesy of the Foundation.

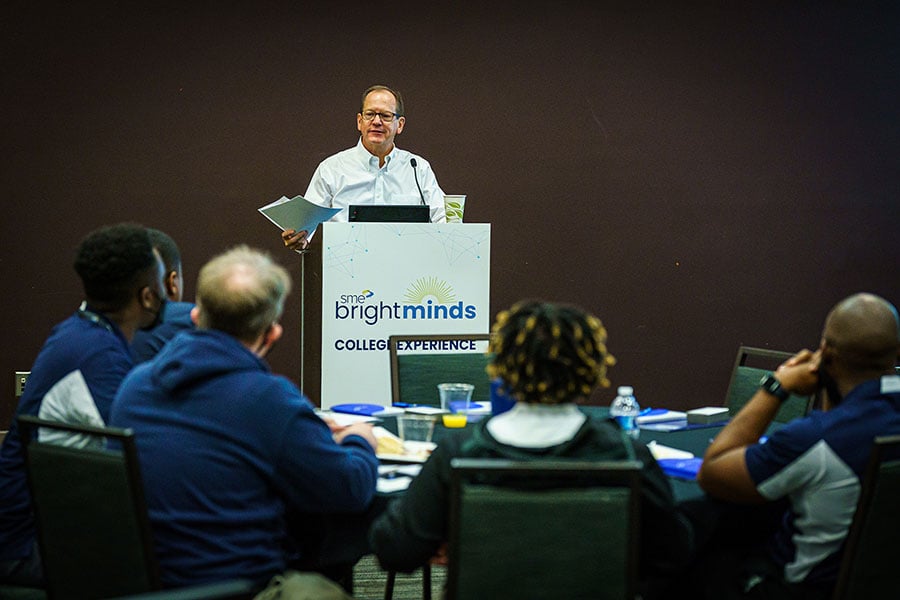

In addition to the high school summits, SME’s Membership organization sponsored a Bright Minds College Experience featuring a day of exploration, networking, and learning. Conducted on the second day of SOUTHTEC, college students from Auburn University and Tuskegee University heard from SME’s Executive Director and CEO, Bob Willig, who shared his “origin story” and interacted with students, sharing experiences and answering questions about manufacturing, career paths and the importance of networking and mentorship.

In addition to the high school summits, SME’s Membership organization sponsored a Bright Minds College Experience featuring a day of exploration, networking, and learning. Conducted on the second day of SOUTHTEC, college students from Auburn University and Tuskegee University heard from SME’s Executive Director and CEO, Bob Willig, who shared his “origin story” and interacted with students, sharing experiences and answering questions about manufacturing, career paths and the importance of networking and mentorship.

In addition, the college students heard from Sheronda Carr, vice president of Membership, Christian Jensen, director of Institutional Giving for the SME Education Foundation and Toni Neary, director of Community Engagement and Workforce Innovation for Tooling U-SME, who discussed student engagement and scholarship opportunities available through the Foundation.

The Digital Solutions Showcase was one of the day’s programming highlights. Students watched demonstrations of cutting-edge technology, including predictive milling, in-situ monitoring, and AI/machine learning. The Accupro® ST series particularly caught their attention as a practical solution for optimized milling performance.

SOUTHTEC is one of four events comprising SME’s Manufacturing Technology Series, which connects decision-makers from diverse industries with leading suppliers of advanced manufacturing technology, equipment, and tooling. The regional events, conducted in odd-numbered years, bring together more than 18,000 participants with 975 exhibitors.